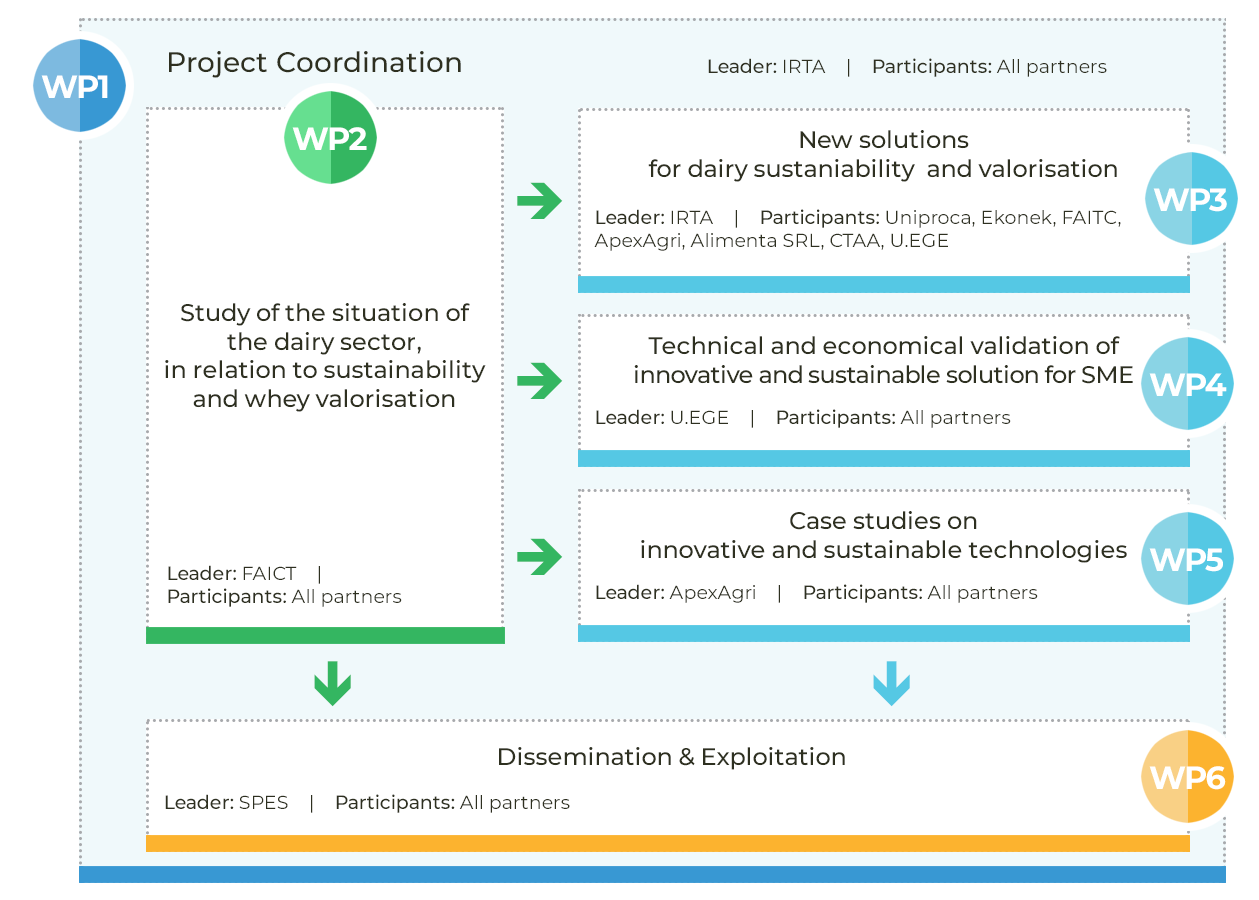

OUR STRATEGY

Dairy market of Mediterranean countries is substantially different from east or north European countries. Cow’s milk is mainly processed into UHT milk and fermented milks, and most of the other ruminant species production (principally ewe milk, but also goat and buffalo’s milk), is transformed into cheeses (Manchego, Pecorino, Beyaz Peynir, Mozzarella, Feta). For example, cheese production from ewe’s milk (Spain, Italy, Greece, Portugal, France, Turkey and Jordania), is about 332,8 million Kg/year [FAO, 2014]. Milk production is also scattered.

However, the dairy sector is very important for the maintenance of rural economy, and for biodiversity and sustainability of rural areas. Dairy products are an important part of the Mediterranean Diet, with high levels of nutritional protein; animals like ewes and goats are more suitable for Mediterranean climate, with grazing capacity in areas where dairy cows cannot do it.

In central and western Europe, large factories process cow’s milk using large automatized full lines, and they can afford to invest in high capacity processing equipment, both for whey concentration and drying, and for the elaboration of high quality protein fractions (to be used as ingredient for infant formula, and for sports drinks). In fact, this valorisation of whey protein is more profitable than cheese elaboration: in some factories, whey protein has turned into the main source of added value, while cheese is just a co-product, sold at low price, just to complement the whey protein income. For example, Germany produces 1.890,9 million Kg/year of cow’s milk cheese, and 348,5 million Kg/year of dry whey powder (cheese whey has 95% of water, so you need to process a whey volume 20 times higher than the weight) [FAO, 2014]. To compete with these very large factories and high volumes of processed milk, the warm countries around the Mediterranean Sea are in large difficulties. They compete with high organoleptic quality dairy products, and with milk from livestock species different from cow. However, lack of appropriate valorisation of whey protein is a serious disadvantage for these companies.

Specific Objectives

Enable small dairies to dry their milk or whey, with the development of a new system to dry liquid foods, with much less investment and energy costs, than traditional systems need at this moment.

Increase the sustainability of the spray-drying process (the most intensive energy user on food processing), by reducing the 20-30 % the energy used (and it can be from renewable source). Afterwards, this emerging technology may then be applied at all kind of dairy powders, and other foods, all around the world.

Development of new whey protein fractions, for infant food and sports drinks, based on goat and ewe’s cheese whey. Afterwards, the new technology may then be applied to cow’s milk/whey, at any place.

New strategy to valorise minor whey volumes, or for dairies without technological competences, based on the elaboration of dairy products with the whey protein produced with the cheese-making.